-

Call Us

(+880) 9613820575

-

Email Us

info@kazispin.com

- Get A Quote

RS30D

ROTOR SPINNING MACHINE

Since the first generation of rotor spinning machines was launched in 2002, the cumulative sales have exiceeded 1,000 spindles, and the number of users has exceeded 1000. Continuous accumulation of process data and research on spinning technology, we understand the development trend of the industry and customer needs throughly, introducing the new generation of rotor spinning machine RS30D with energy saving, high effeciency and intelligence.

- Max Spindles is up to 600 spindles, and the highest rotor design speed of 110,000RPM.

- Modular design and abundant optional accessories to meet the needs of different customers.

- Innovative auto doffing device can be as option, which increase production effeciency greatly.

- More electronic technology applications make machine smarter and more effecient.

RF321G

SHORT FIBER TWO-FOR-ONE TWISTER

Since the launching of the first generation of rotor spinning machine RS10 in 2002, the cumulative sales of RIFA Spinning machine have exceeded 1,500,000 spindles, and the number of clients has exceeded 1200. Through continuous accumulation of process data and research on spinning technology, we have gained insights on the development trend of the industry and customer needs throughly, and hereby introduce the new generation of rotor spinning machine RS51 featured at energy saving, high efficiency and intelligence.

- Digital Piecing

- Flexibility

- High Capacity

- Reasonable Layout

- Large Touch Screen Interface

Proprietary digital piecing model, to ensure piecing strength and shape.

One machine can produce up to 4 varieties at the same time.

The machine max head can reach 1000 spindles and the yam guiding speed max can get 300m/min.

Ergonomic operation height, silver can height is 1200mm, to reduce the labor intensity of textile worker.

Provide more convenient and intuitive operation information experience.

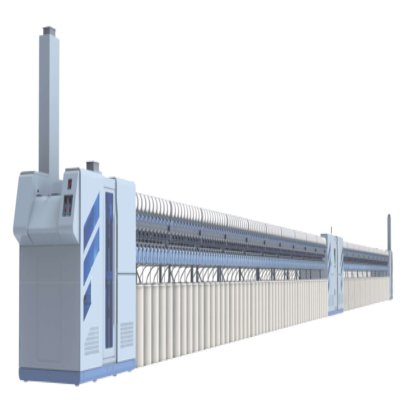

MK8

CARDING MACHINERY

Technical Innovation, Cost Effective Solutions, together with a strong emphasis on providing real practical benefits to the Spinning Industry

Since the company’s inception in 1946, the core value of the company have been to provide real technical and commercial benefits to the textile industry faciliated by innovative engineering to achieve high quality productivity at the lowest possible purchase and owning/operating costs. in today’s ever more challenging environment this methodology becomes ever more important and critical for ensuring the ultimate profitability of the Spinning Mill.

To analyse the total cost for Carding process, the four quantifiable costs are namely:

- Capital (Machinery) Investment

- Power Consumption per Kilo of silver produced

- Direct labour requirement

- Building operation costs

RF321G

SHORT FIBER TWO-FOR-ONE TWISTER

This model is a new type of two-for-one twister that is launched by combining various advantages of the original model and optimizes parts of mechanical structure. It removes the original complicated gearbox structure and changes into the structure of independent transmission of each part, making it convenient for equipment maintenance.

- Advanced processing equipment and reach design experience to ensure equipment performance and stability.

- High-quality spindles and precision winding structure to realize high-quality yarn processing.

- The optimized structure of bobbin creel to meet the requirements of loose bobbin and tight bobbin.

- Whole new electronic forming technology to realize optimal design in the headstock.